Description

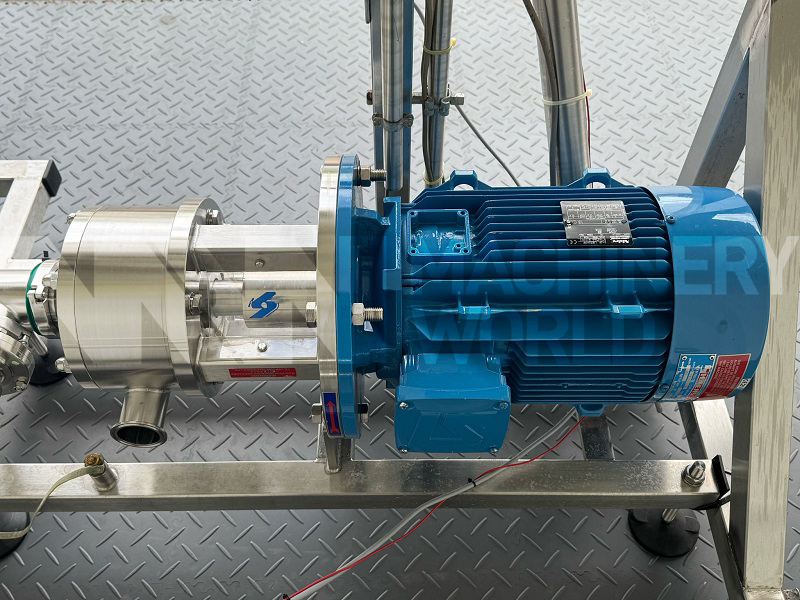

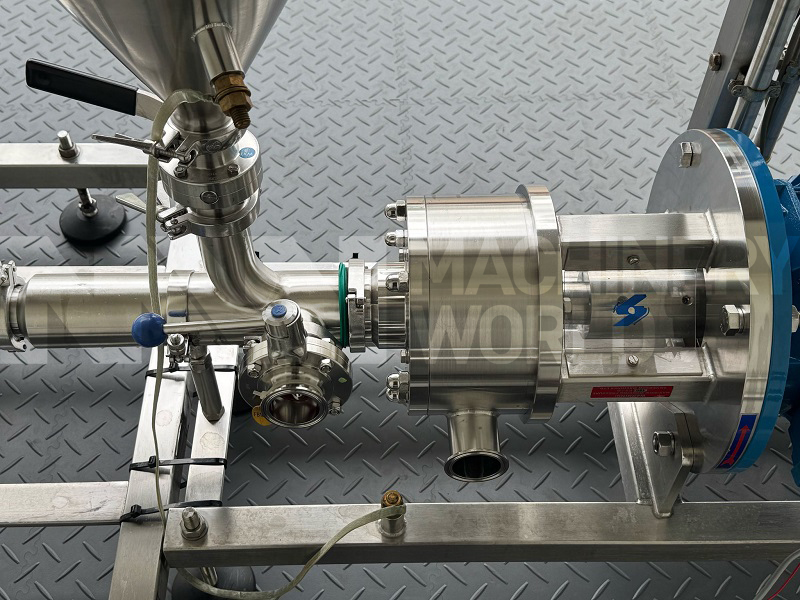

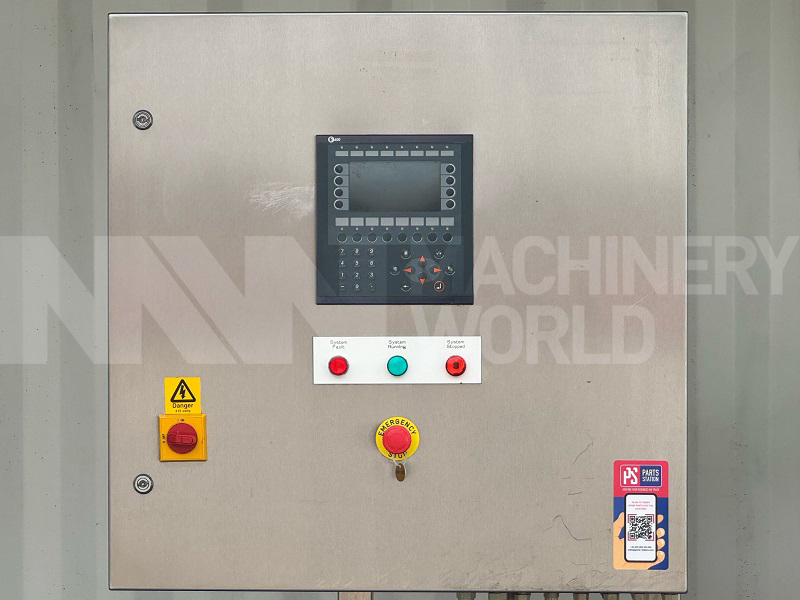

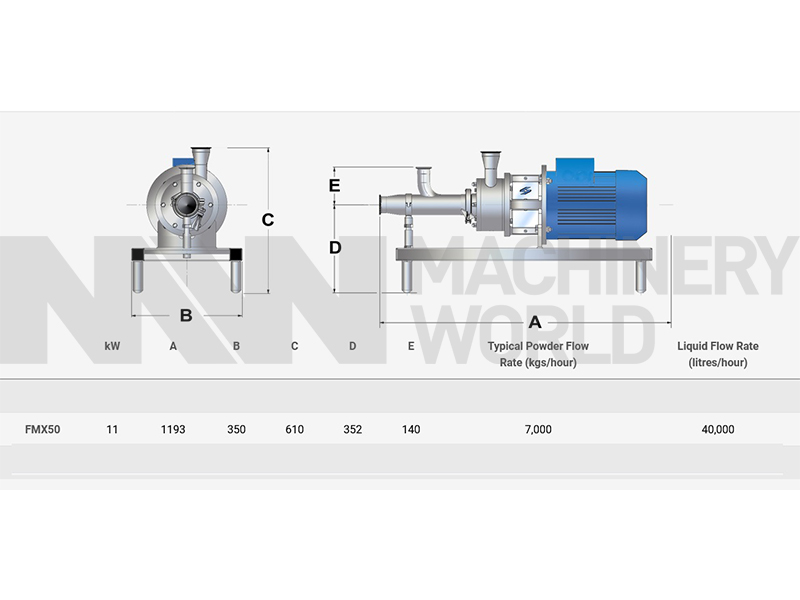

This is a used Silverson FMX50 Flashmix Inline High Shear Mixer Dissolver. Silverson FMX50 Flashmix Inline High Shear Mixer Dissolvers comes with a 11kw Silverson FMX50 Inline High Shear Mixer with a recommended powder feed capacity flow rate of approx 7,000kg per hour (varies depending on the type of powder and solubility of the liquid being pumped through). Silverson FMX50 Flashmix Inline High Shear Mixer Dissolver is specifically designed to wet powders into liquids rapidly. Silverson FMX50 Flashmix Inline High Shear Mixer Dissolver processes various kinds of powders which forms low viscous liquids when dissolved to form a viscous gel. Silverson FMX50 Flashmix Inline High Shear Mixer Dissolver comprises of 11kw Silverson FMX540 Inline High Shear Mixer, Powder Hopper & Electrical Control Panel with Allen Bradley PLC and HMI. Note: Download brochure available on ‘Technical Doc’ link and specification shown below, are for information purpose only, as mentioned on manufacturer’s brochure, and the actual machine’s capabilities and efficiencies might vary.

The Silverson Flashmix introduces an innovative method for mixing powders and liquids. In contrast to traditional powder/liquid mixers that rely on vacuum to draw in powders, the Flashmix actively propels powder into the liquid flow. This technique enables the effective dispersion and hydration of substantial quantities of powders, making it suitable for use at elevated temperatures and with more viscous mixtures. As a result, it extends the benefits of high shear mixing to a broader array of applications that were previously unattainable.

- High powder incorporation rates reaching up to 500 lbs/min

- Product consistently free from agglomerates, ensuring uniformity in every batch

- Capable of performing exceptionally well in high-temperature environments

- Well-suited for applications involving higher concentrations of gums and thickeners

- Reduced aeration for enhanced results

- Sanitary design

- Modular construction provides flexibility for diverse applications and batch sizes

- Low energy consumption without the necessity for additional pumping systems

- Ergonomically designed at a low level for user convenience

- User-friendly: the Flashmix is straightforward to install, operate, and clean

Specification

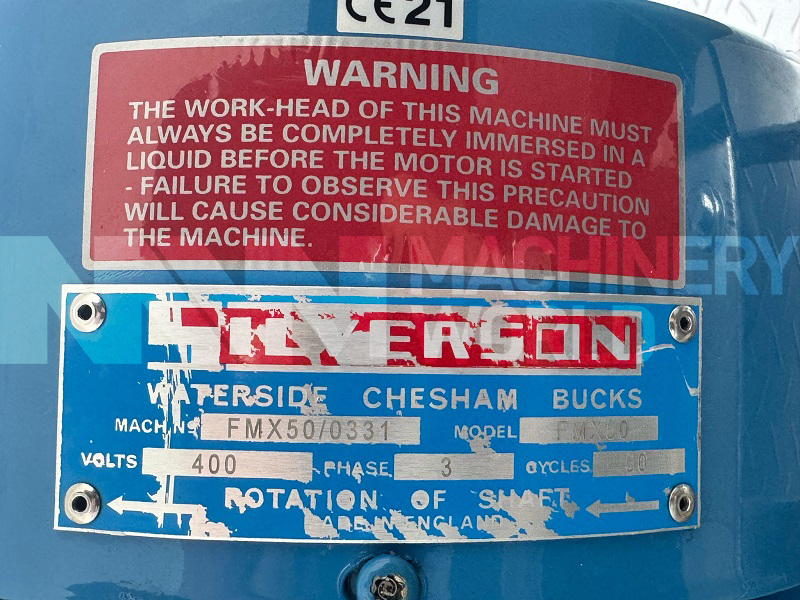

- Make: Silverson Machines Ltd, England

- Type: Flashmix FMX50

- Model: Flashmix Inline High Shear Mixer Dissolver Homogeniser

- Serial Number: FMX50/0331

- Year of Manufacture: 2021

- Construction: 316 grade Stainless Steel Product Contact Parts

- Typical Powder Flow Rate: 7,000kg per hour (Varies depending on the type of powder and solubility of the liquid being pumped through)

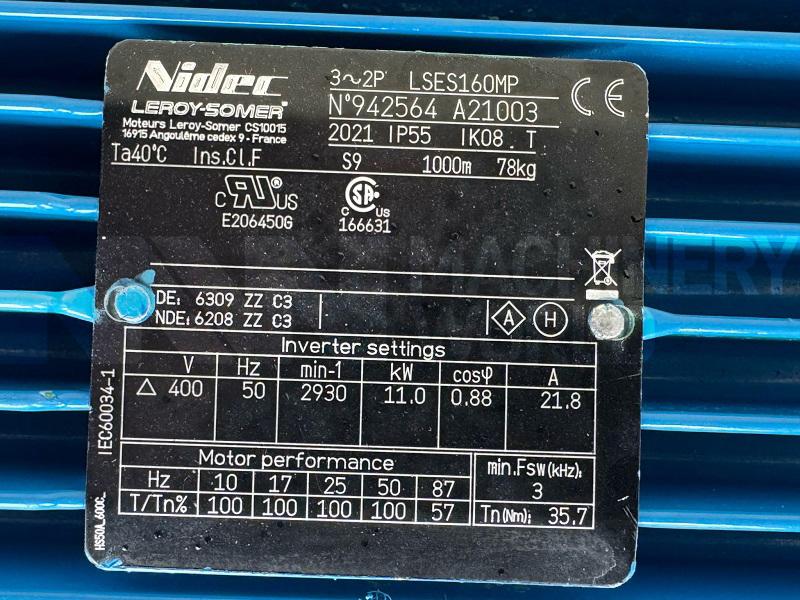

- Motor Power:

Silverson Inline High Shear: 11kw, 3-Ph & 50Hz - Standard Hopper Volume: Approx. 40 Litres

- Control Panel: Comes Fully Integrated with Allen Bradley PLC and Mitsubishi E600 HMI

- Additional Details: Silverson Flashblend Mixer comes built on Stainless Steel Skid.

Country of Manufacture

England

Twitter

Twitter Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn