Description

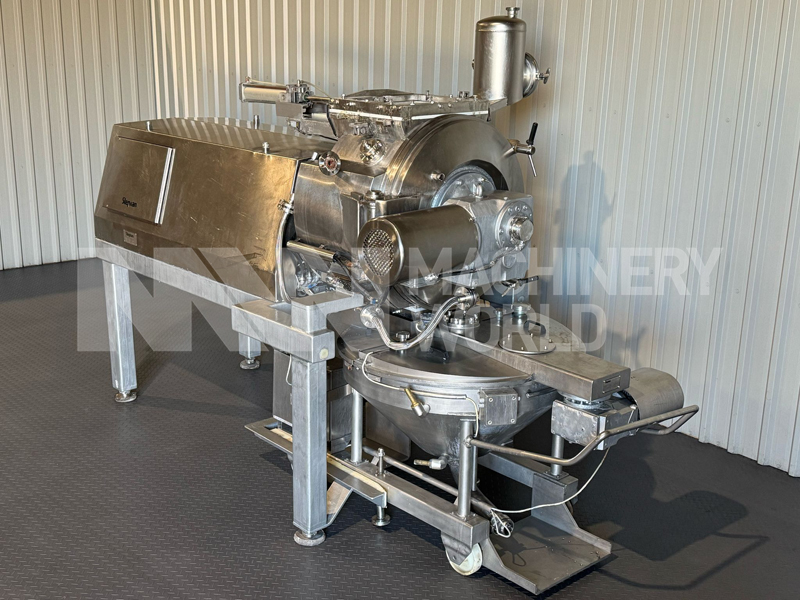

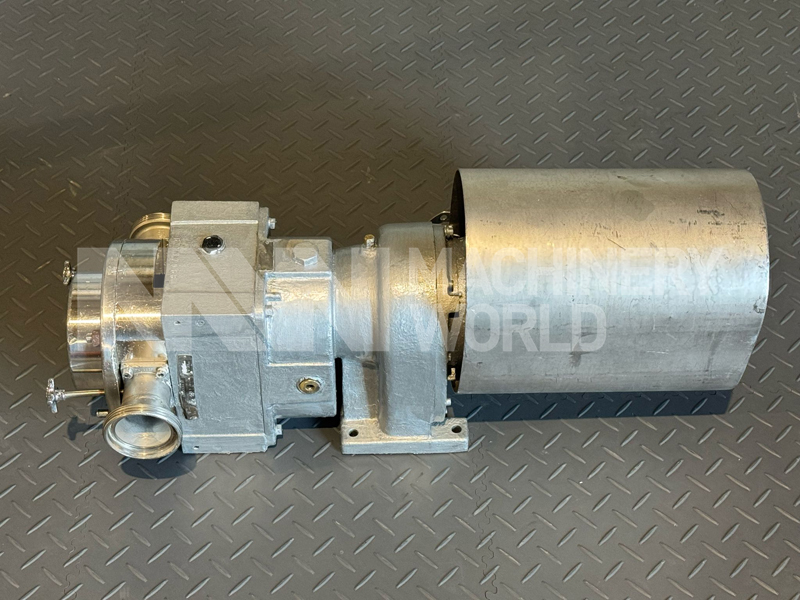

The Stephan Combicut TC SK 300 is a multi-functional machine. It is used successfully for a wide range of applications in the food industry. Besides cutting, mixing and dispersing, heating and cooling can be done in the same system. The integrated vacuum system avoids oxidation and ensures a high product quality.This is a Used Stephan Combicut TC SK 300 and includes Feed In Hopper, Euro Bin Lifter – Tipper and Control Panel.

Advantages of Stephan TC SK 300

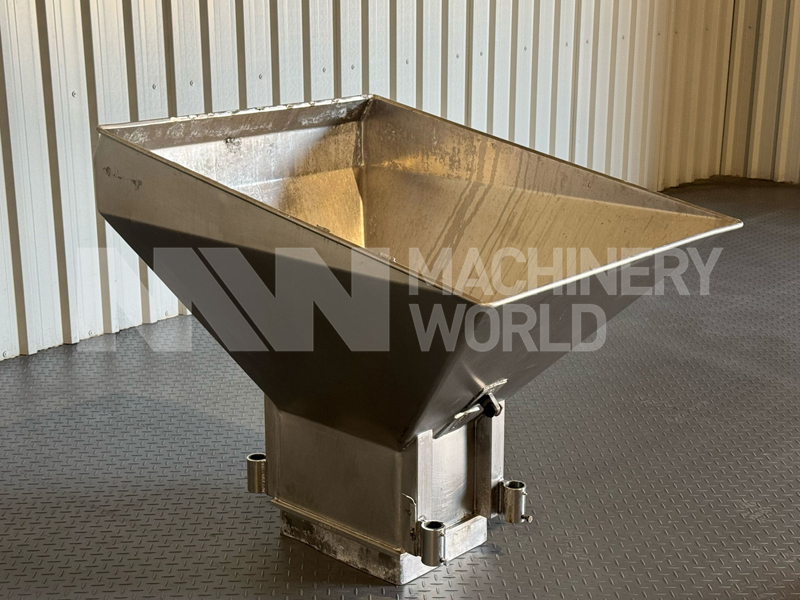

- Loaded from the top via Slide Door

- Bottom discharge without residue inside the vessel

- Shorter batch processing times

- Can be configured to suit various product applications

- Machine can be easily integrated with production line

- Complete homogenous mixing of products

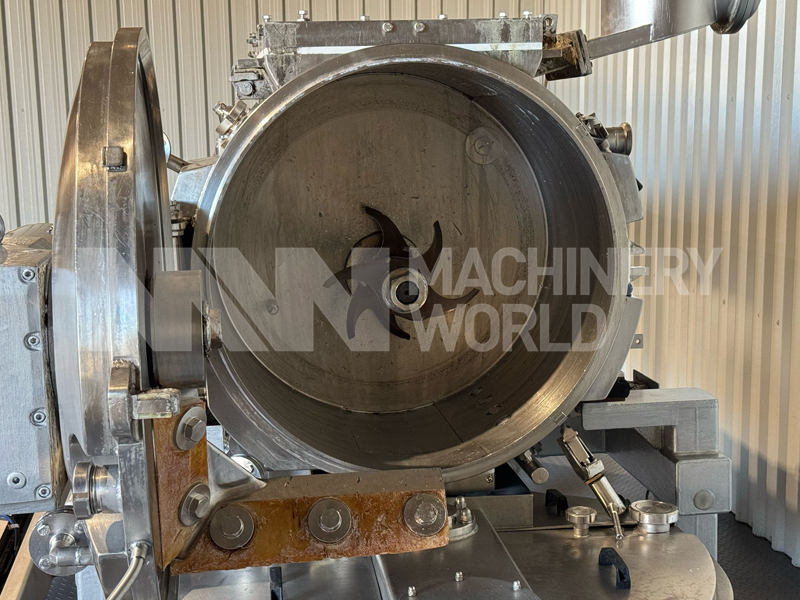

- Highly efficient cutting mechanism

Product Application

- Processed Cheese

- Various Fresh Cheese Preparations

- Imitation Cheese & Pasta Filata

- Cold Pack Cheese

- Dressings & Sauces

- Baby Food

- Confectionery Products

- Butter Preparations

- Almond Paste & Marzipan

- Mayonnaise & Ketchup

- Horseradish

- Liver Pate

- Surimi

Features

- Manufacturer: Stephan GmbH

- Model: Combicut TC SK 300

- Function: Multi Purpose Universal Mixer Cooker

- Construction: 304 grade Stainless Steel

- Machine Number: 716.449

- Serial Number: 2837391

- Bowl Content: Approx 330 Litres

- Batch Quantity: Approx 220 Litres (Varies depending on type of product)

- Motor Power: 72kw, 3-Ph & 50Hz

- Vacuum: Yes, Vacuum Rated

- Maximum Pressure: 1.5 Bar

- Maximum Operating Temperature: 110 deg C

- Maximum Operating Pressure in Double Jacket: 2 Bar

- Maximum Operating Temperature in Double Jacket: 134 deg C

- Maximum Compressed Air: 6 to 8 bar

- Recommended Steam Requirement: Approx 500 kg per hour

- Steam Pressure: 6 to 8 Bar

- Includes Feed Hopper, Euro Bin Lifter – Tipper & Control Panel

- See ‘Technical Doc’ link for general brochure

Country of Manufacture

Germany

Download Technical Doc

Twitter

Twitter Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn